Our Expertise

New Generation of Electric-Turbo-Compounding (ETC) for Reciprocating Engine Generator Sets

This article presents the development, design methodology, and real‑world performance of a new generation Electric Turbo‑Compounding (ETC) system created by Bowman Power Group for use on diesel and gas reciprocating engine generator sets.

Conclusion

The article concludes that the new ETC generation:

- Achieves the targeted 40% cost reduction

- Is on track for 50% improved reliability

- Successfully integrates numerous engineering innovations

- Has been released into full series production

It positions ETC as a rapidly maturing, commercially viable technology for improving the efficiency and competitiveness of large‑scale power generation operations.

Bowman eTurbo Systems for Datacentre Applications

As global AI adoption accelerates, datacentres are experiencing unprecedented growth in compute demand, driving the need for more powerful, efficient and resilient on‑site energy systems. Natural Gas (NG) Internal Combustion Engine (ICE) microgrids are rapidly emerging as a practical solution, offering fast deployment, long‑duration resilience, and significantly lower operating costs and emissions compared to traditional diesel systems.

Our eTurbo Systems enable the latest high‑efficiency NG ICE gensets to meet both datacentre backup and prime‑power requirements without the compromises typically associated with fast‑start or high‑dynamic‑response applications. Through advanced electrical boosting, ultra‑fast response control, and the ability to generate power directly from the turbocharger shaft, Bowman eTurbo technologies deliver:

- Up to 36% reduction in UPS requirements during backup scenarios

- Up to 6% reduction in installed site cost

- Up to 6% reduction in fuel consumption and CO₂ emissions

- Ultra‑fast 29–37 second start-to-full-load capability

- Stable, emissions‑compliant operation across aggressive AI training load cycles

This unique combination allows datacentres to unlock best‑in‑class performance and power quality even during extreme load swings from modern GPU clusters—without sacrificing efficiency, emissions compliance, or resilience. As grid constraints continue to slow datacentre expansion globally, our eTurbo-enabled NG microgrids provide a flexible, future‑proof pathway to scalable AI infrastructure, supporting both immediate power needs and long‑term economic optimisation..

Electric turbocharging – A path to increased lean burn gas genset efficiency together with diesel like transients

Advances in high‑speed electrical machines (HSEMs) and power electronics have enabled new electric turbocharging technologies for internal combustion engines, including electric turbo‑compounding (ETC), electric compressors (E‑Comp), and electric turbochargers (E‑Turbo). This paper presents Bowman Power Group’s applied experience with these technologies and evaluates their steady‑state and transient performance on a modern high‑speed, high‑BMEP lean‑burn natural gas genset. Through combined simulation and experimental correlation, it is shown that optimised ETC and E‑Turbo configurations can increase full‑load electrical efficiency by up to 2.0 percentage points under ISO conditions.

Additionally, E‑Turbo and E‑Comp architectures significantly improve transient response, achieving diesel‑like load acceptance and enabling rapid emergency‑start performance. The work also analyses combustion, scavenging, knock, emissions, and mechanical considerations associated with turbine downsizing and HSEM integration. The results identify the optimal application scenarios for each technology, demonstrating that ETC maximises base‑load efficiency, while E‑Turbo offers the best overall balance of efficiency gain, load flexibility, and transient performance for broader power generation and hybrid applications.

Design of electrified turbomachinery for use in modern industrial hybrid powertrains

Electrified turbomachinery offers a pathway to improving efficiency, transient response, and emissions performance in heavy‑duty and industrial hybrid powertrains. While such systems are increasingly common in passenger vehicles, their adoption in larger engines has lagged due to demanding power, thermal, packaging, and durability requirements.

This paper documents the development of two key technologies—an electric compressor and an electric turbocharger, both systems integrate high‑speed electrical machines with turbomachinery stages to provide on‑demand boost, reduce turbo lag, recover exhaust energy, and support hybrid powertrains. The work outlines the aerodynamic, mechanical, thermal, and power‑electronic constraints guiding the design, including bearing selection, rotor inertia optimisation, high‑temperature cooling strategies, and motor‑control methodology.

Simulation results demonstrate that electric compressors require fast, sensored startup for optimal low‑speed boosting, whereas electric turbochargers can operate sensorlessly due to continuous turbine rotation. The study concludes that despite the multidisciplinary engineering challenges, electrified turbomachinery can be successfully adapted for heavy‑duty applications, enabling improved drivability, lower fuel consumption, and reduced emissions, with prototypes moving into physical testing.

Development and Validation of a 2-stage Electric Compressor System to Overcome Turbocharger Lag on High-Speed Internal Combustion Engines

This paper presents the development of the StartIQ™ system, a two‑stage high‑speed electric compressor designed to eliminate turbocharger lag in high‑speed natural‑gas, biogas, and hydrogen generator sets. Modern lean‑burn engines use large, high‑efficiency turbochargers that perform well at full load but respond poorly at low load or cold start due to high inertia and low exhaust temperatures. To address this, the StartIQ™ system injects compressed air into the exhaust manifold upstream of the turbocharger, rapidly accelerating the turbine and enabling fast load acceptance. The design uses a 55 kW permanent‑magnet electrical machine that can accelerate from rest to operating speed in under one second, with no cooling or lubrication systems required. Power‑electronics design, surge‑protection strategies, and control logic were optimised to ensure repeatable performance across varying exhaust pressures.

Validation was performed on a UK 20 MWe gas‑peaking site using ten 2 MW gensets. The system improved cold‑start load‑ramp times from roughly 90 seconds to under 10–15 seconds, enabling performance previously only associated with diesel gensets. Over 10,000 automated starts demonstrated >99.9% reliability, and emissions during transients were reduced by 80–90% due to elimination of enrichment. The paper concludes that StartIQ™ provides a simple, retrofit‑ready solution for meeting modern grid‑balancing requirements without compromising engine durability, steady‑state performance, or emissions

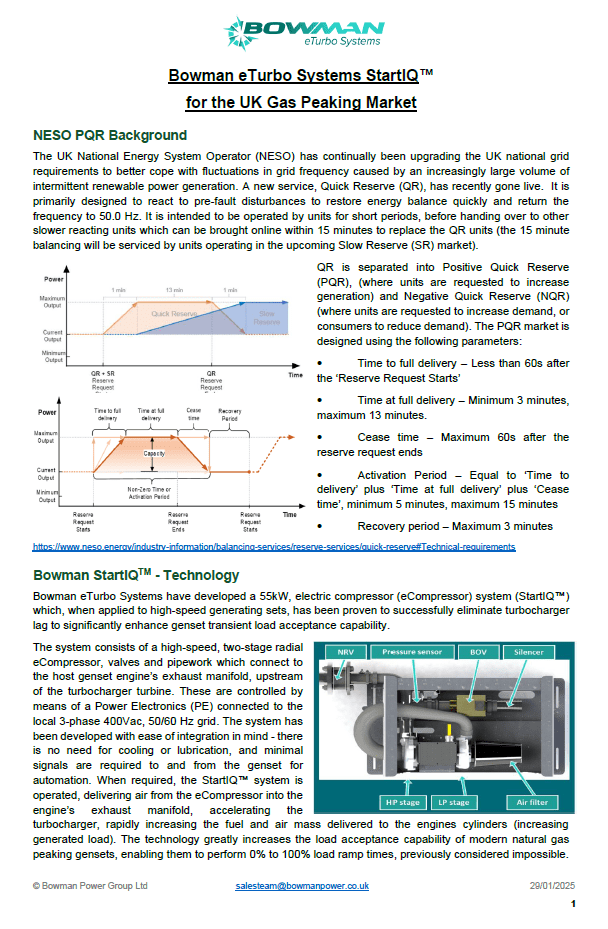

Bowman eTurbo Systems StartIQ™ for the UK Gas Peaking Market

This paper explains how our StartIQ™ system can help gas‑powered generator sets take part in the UK’s new Quick Reserve (QR) electricity market. Because renewable energy like wind and solar can fluctuate suddenly, the grid now needs fast‑acting power sources that can react within seconds when frequency drops. Traditionally, gas engines haven’t been fast enough because their turbochargers take too long to spool up, especially when engines start cold.

StartIQ™ fixes this by blasting compressed air into the engine’s exhaust manifold to instantly spin up the turbocharger. This removes the usual turbo lag and lets a genset jump from zero to full load in about 10 seconds. In real installations, complete start‑to‑full‑power takes less than 60 seconds, which meets the QR requirement easily. The system is simple to install—it doesn’t need oil, coolant, or major engine changes—and can be controlled with just a handful of signals from the generator.

Field results have been very strong. StartIQ™ has been tested on three different engine platforms and deployed at a full 20 MW peaking site in the UK. Across more than 10,000 automated starts, reliability has been above 99.9%, and every unit has consistently met the strict PQR response times. The system also dramatically cuts fuel use and emissions during ramp‑up (by 80–90%) because the engine no longer needs to run wasteful enrichment strategies while waiting for the turbo to catch up.

Development of eCompressor system to improve high-speed engine transient load acceptance

This paper explains how StartIQ™ can fix a major shortcoming of modern high‑speed gas engines: their inability to respond quickly when a sudden jump in power is required. These engines rely on large, efficient turbochargers that work well at full load, but they spin up slowly and perform poorly at low load or when the engine is cold. As a result, these engines cannot match the instant response of diesel generators, which limits their use in fast‑acting grid‑support applications like the UK’s new Quick Reserve service.

StartIQ™ solves this problem by using a powerful two‑stage electric compressor to push pressurised air into the engine’s exhaust system before the turbocharger. This instantly accelerates the turbo, allowing the engine to produce power much faster than it normally would. The system is compact, does not need oil or coolant, works with any fuel type (natural gas, biogas, hydrogen), and is designed to bolt onto existing generator sets with minimal changes.

The paper describes how the system was engineered, including compressor design, high‑speed motor development, power‑electronics requirements, surge‑protection strategies, and integration with different engines. Testing shows that StartIQ™ can cut load‑ramp times from roughly a minute to around 10 seconds—or even as fast as 6 seconds depending on the engine. This makes gas engines almost as responsive as diesel units. The system has been tested on multiple engine types and is already operating successfully on a full 20 MW UK peaking site, where it has delivered more than 10,000 automated fast starts.

Beyond grid‑connected applications, StartIQ™ also improves performance in off‑grid systems, island‑mode operation, backup power, and emergency standby where fast load acceptance is essential. It can even support engines with multi‑stage turbocharging. In summary, StartIQ™ gives modern gas engines the fast‑response capability they’ve been missing, allowing them to meet new grid requirements, reduce emissions during startup, and operate reliably under demanding conditions.