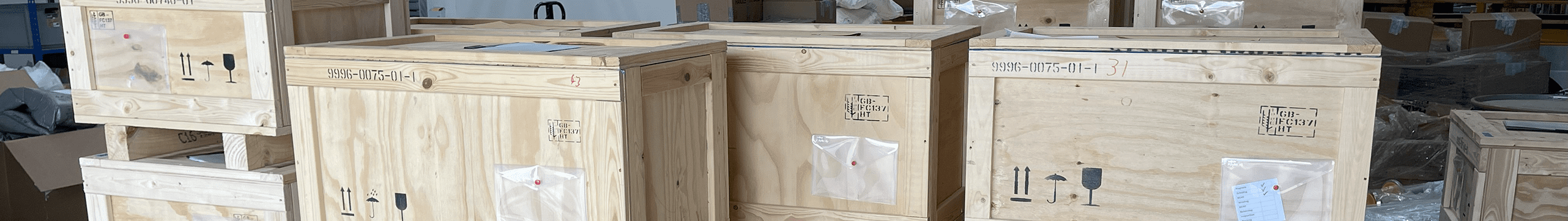

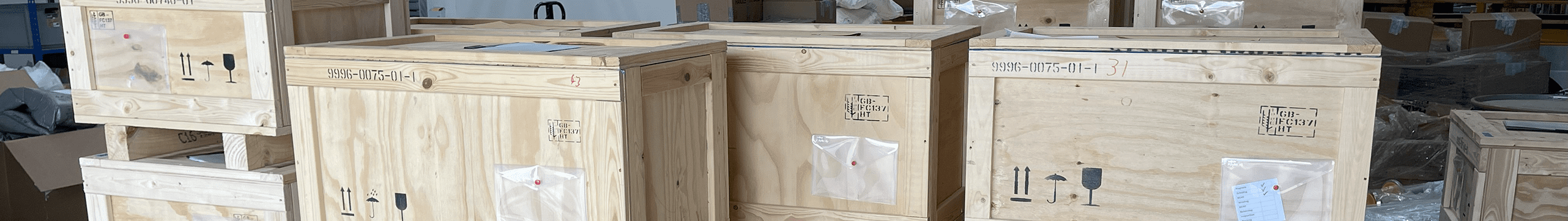

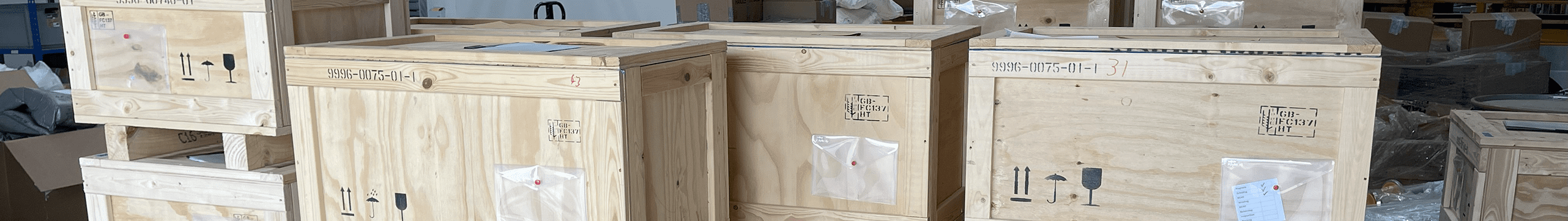

It may look like an innocuous stack of wooden packing crates, but the above image has enormous significance for us and our growth story.

After resetting the strategy of the business at the beginning of 2021 to focus substantially on co-development of eTurbo Systems solutions with engine and turbocharger OEMs, and the move to new premises to establish the Turbo Systems Electrification Centre (TSEC) for advanced electric machines manufacturing and power electronics assembly, we have now reached the major milestone of launching series production at our Southampton, UK, site.

Following two years of setting up new facilities and advanced manufacturing process development and pilot production, we have now completed a volume capacity production demonstration under the close scrutiny of its first series production OEM partner. With specific focus on process controls and stringent quality control, all governed by its combined ISO9001, 14001 and 45001 business management system, we completed the rate demonstration with time to spare. Some of the output is shown in the image, following final pre-delivery inspection, packing and declaration to our partner that it's ready for collection.

This is a truly significant milestone in our journey, marking the move back into manufacturing and, importantly, a sustainable one backed by long-term supply agreements and close partnership. We look forward to transitioning other product co-developments, with a range of partners, into long-term manufacturing opportunities, securing our position as a key player in the advanced electric machines and power electronics sector - a sector central to UK industrial strategy.

We would like to take the opportunity to thank all the partners, suppliers and advisors who have supported us in the new strategy for the business and guided us to this point.

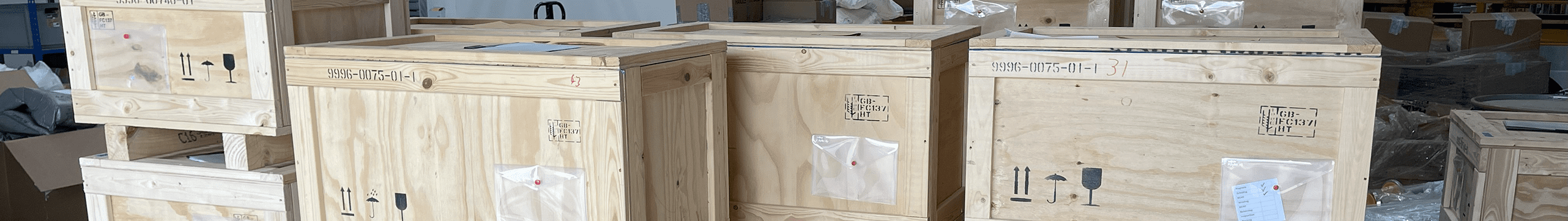

It may look like an innocuous stack of wooden packing crates, but the above image has enormous significance for us and our growth story.

After resetting the strategy of the business at the beginning of 2021 to focus substantially on co-development of eTurbo Systems solutions with engine and turbocharger OEMs, and the move to new premises to establish the Turbo Systems Electrification Centre (TSEC) for advanced electric machines manufacturing and power electronics assembly, we have now reached the major milestone of launching series production at our Southampton, UK, site.

Following two years of setting up new facilities and advanced manufacturing process development and pilot production, we have now completed a volume capacity production demonstration under the close scrutiny of its first series production OEM partner.

With specific focus on process controls and stringent quality control, all governed by its combined ISO9001, 14001 and 45001 business management system, we completed the rate demonstration with time to spare. Some of the output is shown in the image, following final pre-delivery inspection, packing and declaration to our partner that it's ready for collection.

This is a truly significant milestone in our journey, marking the move back into manufacturing and, importantly, a sustainable one backed by long-term supply agreements and close partnership. We look forward to transitioning other product co-developments, with a range of partners, into long-term manufacturing opportunities, securing our position as a key player in the advanced electric machines and power electronics sector - a sector central to UK industrial strategy.

We would like to take the opportunity to thank all the partners, suppliers and advisors who have supported us in the new strategy for the business and guided us to this point.

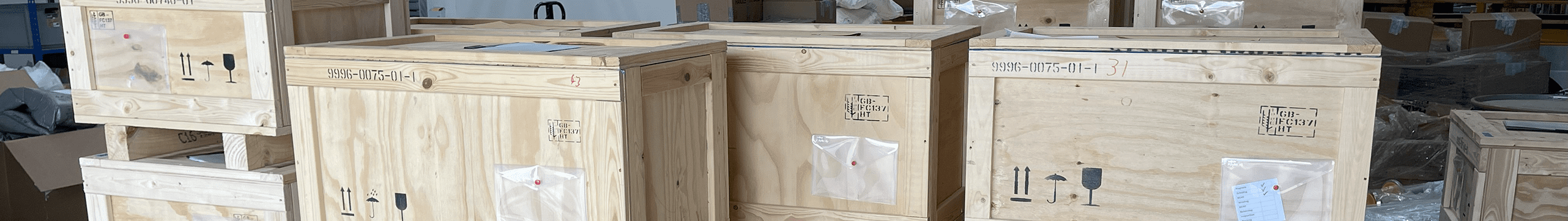

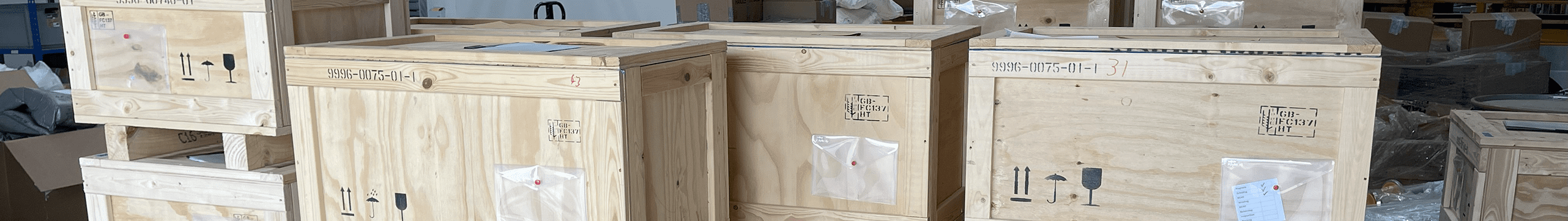

It may look like an innocuous stack of wooden packing crates, but the above image has enormous significance for us and our growth story.

After resetting the strategy of the business at the beginning of 2021 to focus substantially on co-development of eTurbo Systems solutions with engine and turbocharger OEMs, and the move to new premises to establish the Turbo Systems Electrification Centre (TSEC) for advanced electric machines manufacturing and power electronics assembly, we have now reached the major milestone of launching series production at our Southampton, UK, site.

Following two years of setting up new facilities and advanced manufacturing process development and pilot production, we have now completed a volume capacity production demonstration under the close scrutiny of its first series production OEM partner.

With specific focus on process controls and stringent quality control, all governed by its combined ISO9001, 14001 and 45001 business management system, we completed the rate demonstration with time to spare. Some of the output is shown in the image, following final pre-delivery inspection, packing and declaration to our partner that it's ready for collection.

This is a truly significant milestone in our journey, marking the move back into manufacturing and, importantly, a sustainable one backed by long-term supply agreements and close partnership. We look forward to transitioning other product co-developments, with a range of partners, into long-term manufacturing opportunities, securing our position as a key player in the advanced electric machines and power electronics sector - a sector central to UK industrial strategy.

We would like to take the opportunity to thank all the partners, suppliers and advisors who have supported us in the new strategy for the business and guided us to this point.