Our Performance Engineering Director, Keith Douglas gives an update on the StartIQ™ fast start eCompressor validation programme, now that operational trials are underway.

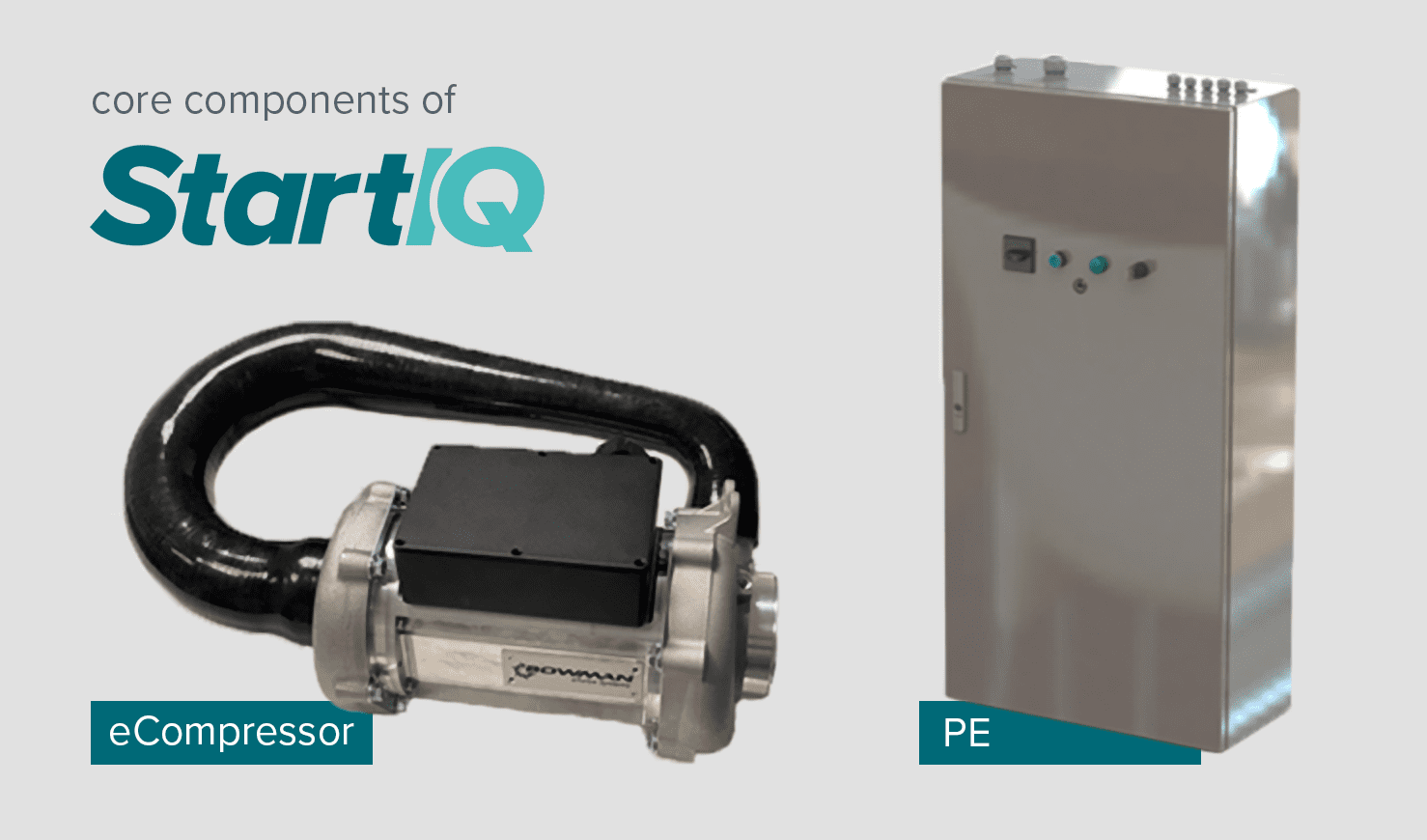

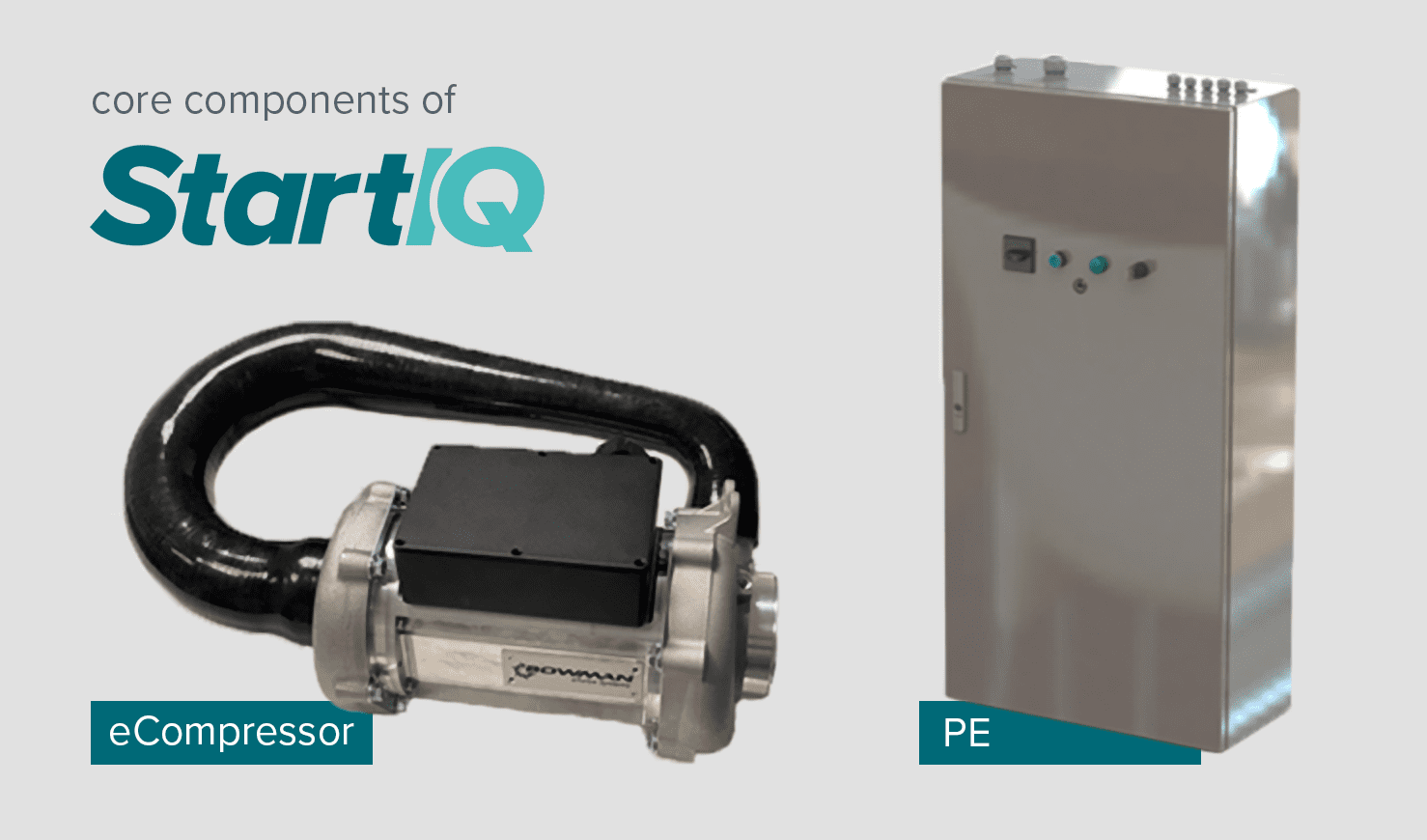

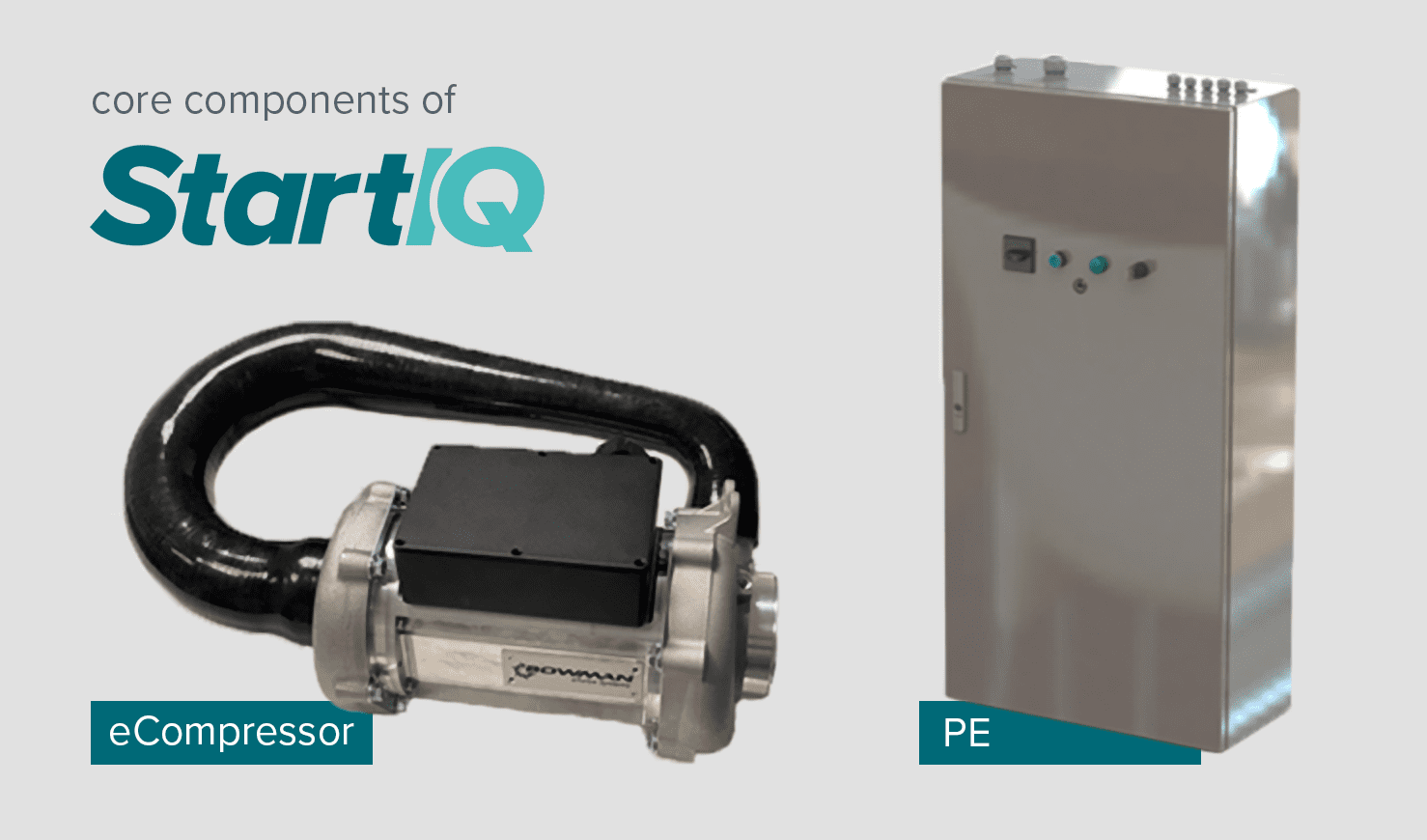

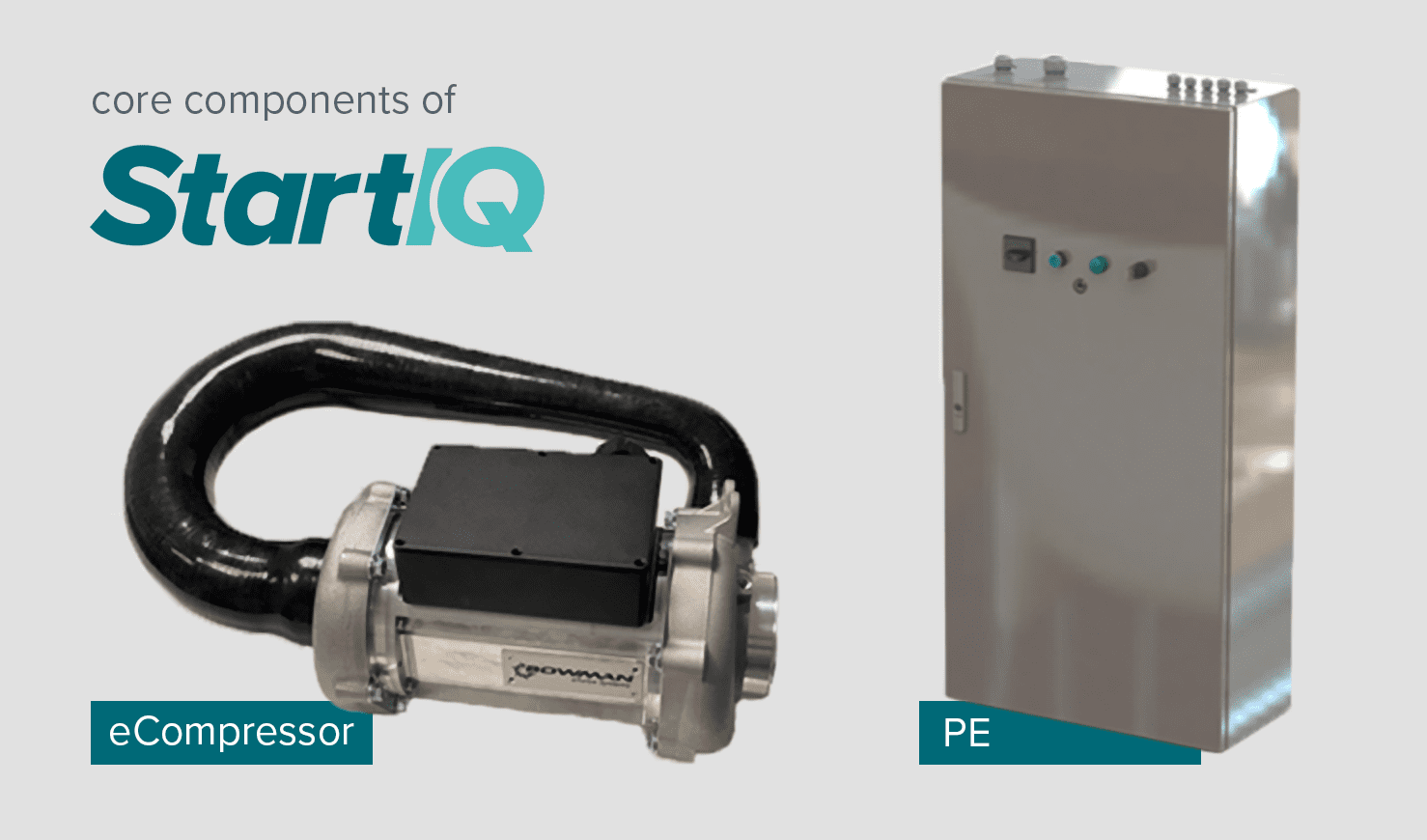

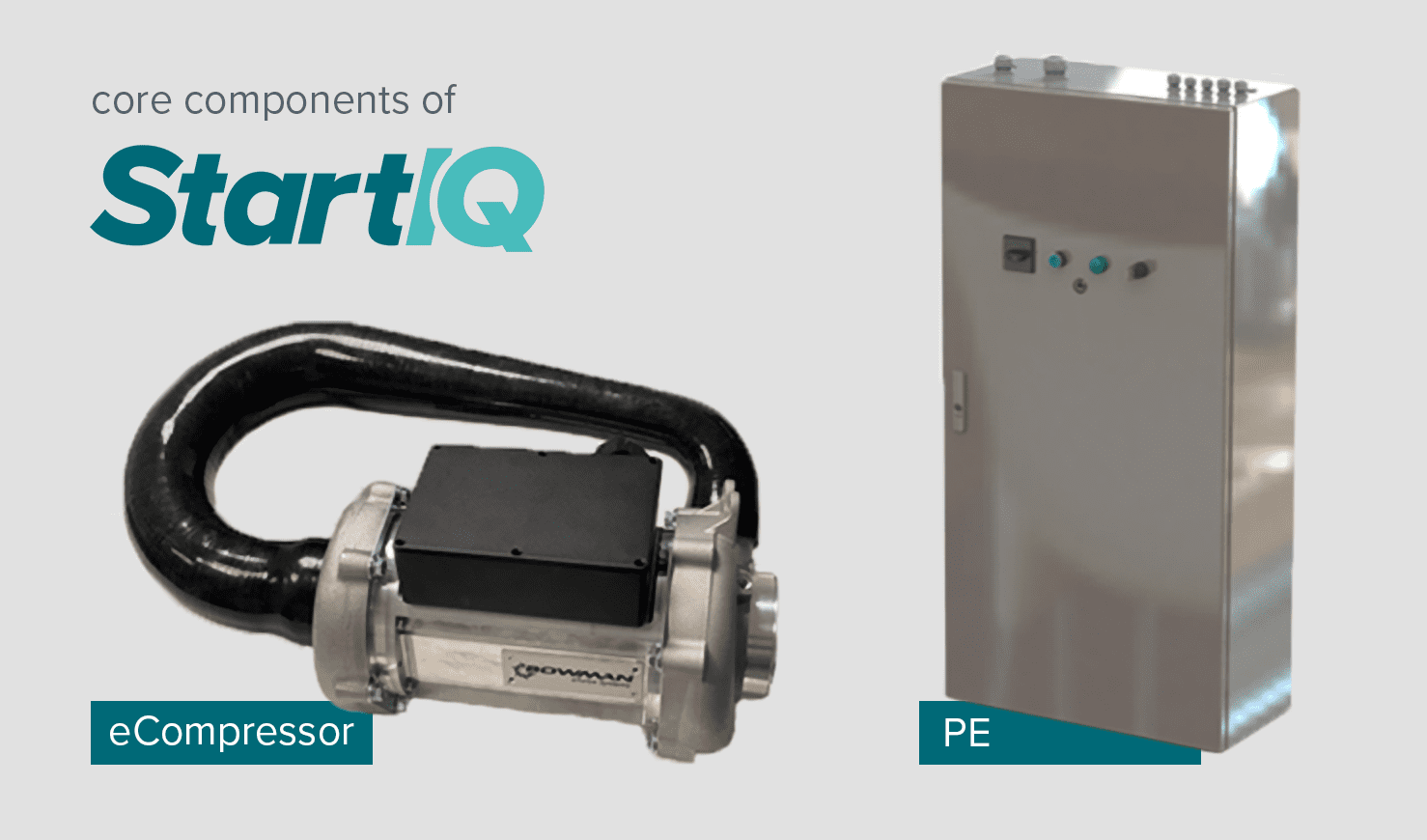

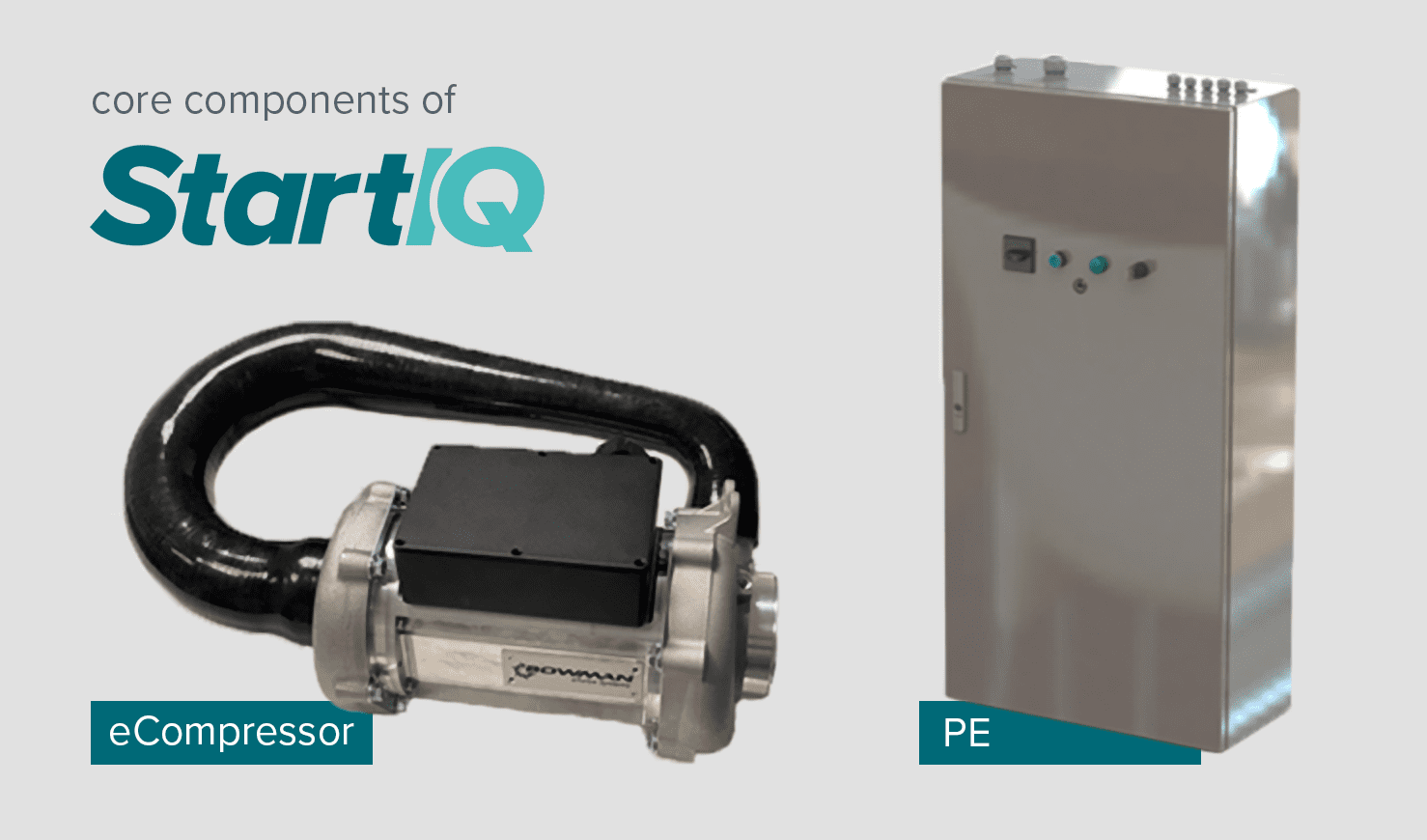

We have recently been proving our newly developed fast-start electric compressor (eCompressor) technology on a natural gas peaking genset supporting the UK National Grid – we are calling this product StartIQ™.

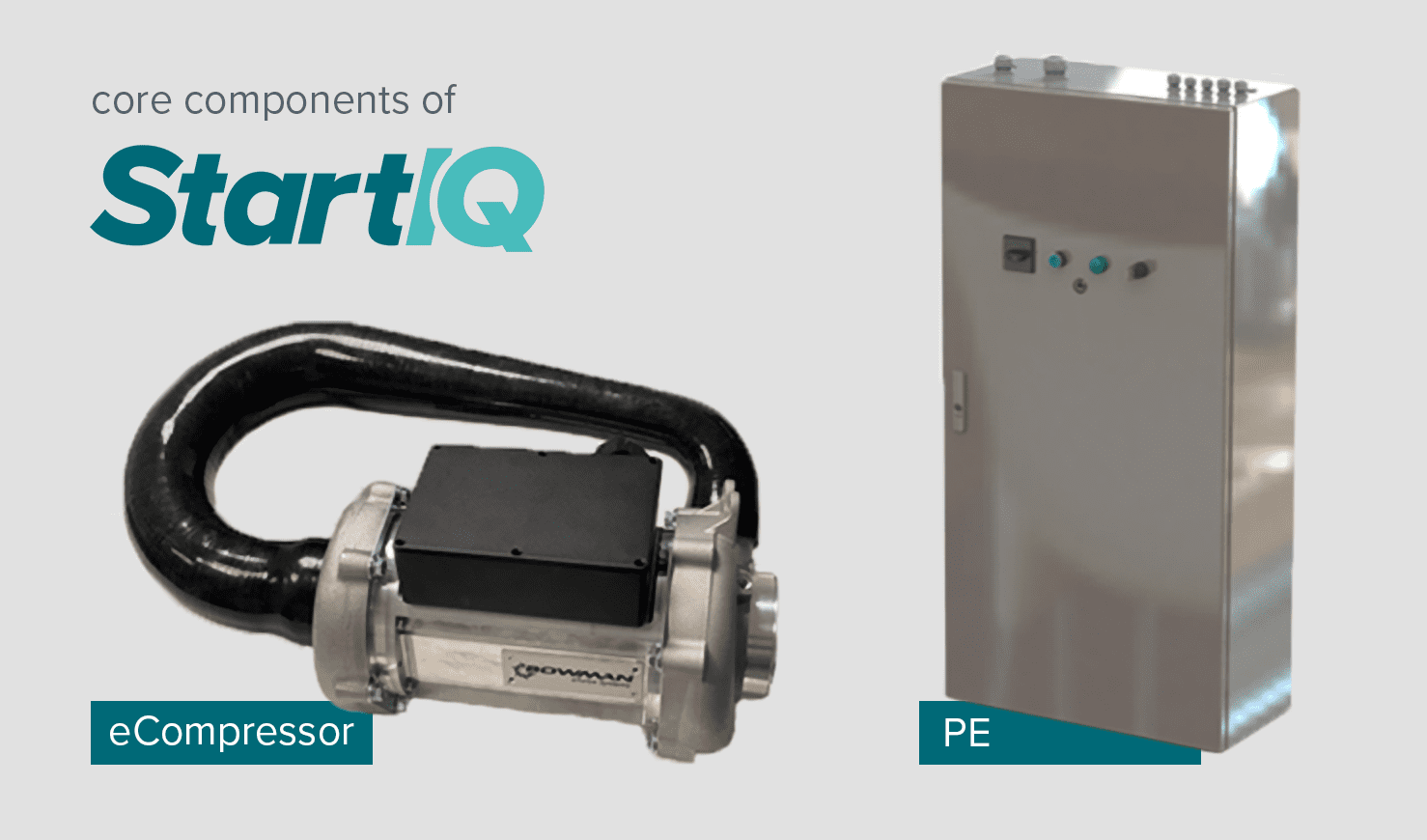

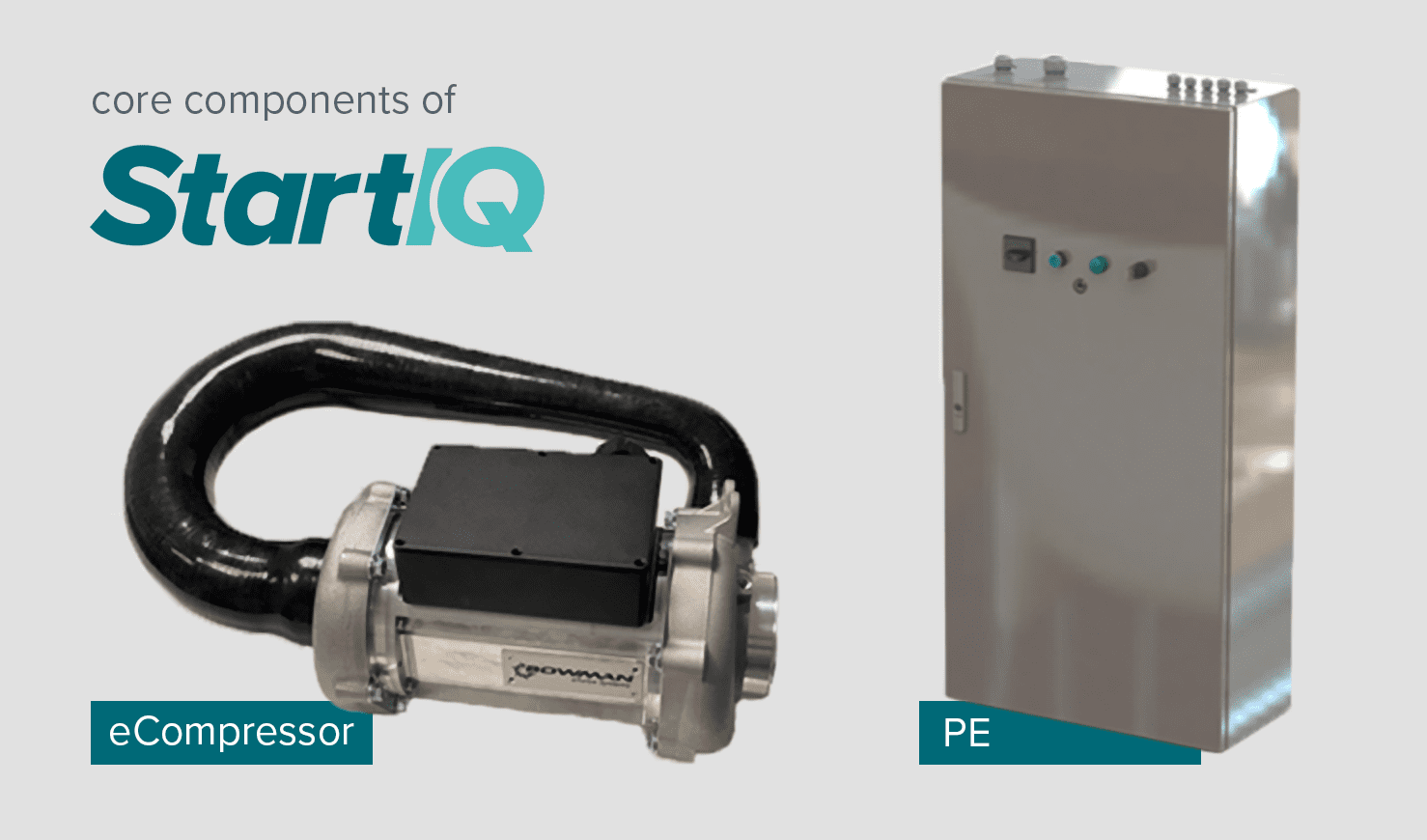

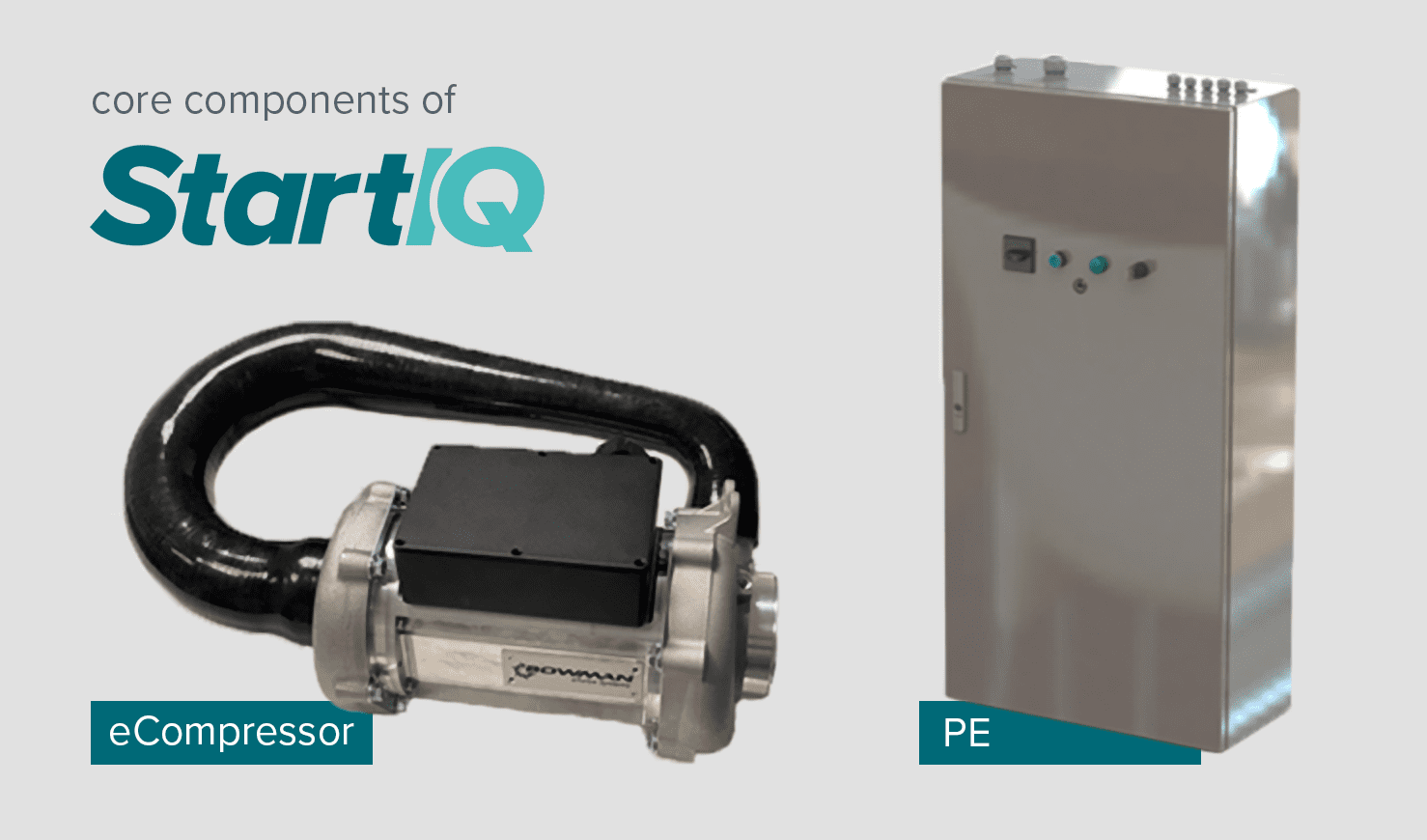

Our StartIQ™ 2-stage eCompressor is connected to the genset internal combustion engine’s (ICE) exhaust manifold in a novel, patent-pending approach development by Bowman, injecting air during load ramps to help spin up the turbocharger faster.

When called upon by the grid, the genset immediately starts and spins up to rated speed, and as soon as it successfully synchronises with the grid, StartIQ™ kicks into action. The eCompressor accelerates from rest to more than 80,000rpm in less than 1 second, delivering ~0.4kg of air per second to the ICE’s exhaust manifold, entirely eliminating turbocharger lag all the way to 100% genset load. Once 100% genset load is achieved StartIQ™ disengages, allowing the genset to run at full load for as long as the grid requires.

The result? 0 to 100% Genset load ramp time, CO2 emissions and NOx emissions all reduced by ~90% versus the status quo.

The benefit for the customer? Reduced fuel and carbon trading costs per start, which alone give a favourable payback for StartIQ™. But on top, StartIQ™ improves the genset’s cost competitiveness for shorter duration runs, allowing the number of grid actions performed (and therefore genset revenue) to be increased on a daily basis.

The benefit for the UK National Grid and its consumers? The response times of Gigawatts of gas peaking assets in the UK can be reduced using StartIQ™, providing greater flexibility to the UK National Grid as more and more renewables come online.

Keep an eye out for our press release with our first partner adopting StartIQ™ in the coming weeks.

Our Performance Engineering Director, Keith Douglas gives an update on the StartIQ™ fast start eCompressor validation programme, now that operational trials are underway.

We have recently been proving our newly developed fast-start electric compressor (eCompressor) technology on a natural gas peaking genset supporting the UK National Grid – we are calling this product StartIQ™.

Our StartIQ™ 2-stage eCompressor is connected to the genset internal combustion engine’s (ICE) exhaust manifold in a novel, patent-pending approach development by Bowman, injecting air during load ramps to help spin up the turbocharger faster.

When called upon by the grid, the genset immediately starts and spins up to rated speed, and as soon as it successfully synchronises with the grid, StartIQ™ kicks into action. The eCompressor accelerates from rest to more than 80,000rpm in less than 1 second, delivering ~0.4kg of air per second to the ICE’s exhaust manifold, entirely eliminating turbocharger lag all the way to 100% genset load. Once 100% genset load is achieved StartIQ™ disengages, allowing the genset to run at full load for as long as the grid requires.

The result? 0 to 100% Genset load ramp time, CO2 emissions and NOx emissions all reduced by ~90% versus the status quo.

The benefit for the customer? Reduced fuel and carbon trading costs per start, which alone give a favourable payback for StartIQ™. But on top, StartIQ™ improves the genset’s cost competitiveness for shorter duration runs, allowing the number of grid actions performed (and therefore genset revenue) to be increased on a daily basis.

The benefit for the UK National Grid and its consumers? The response times of Gigawatts of gas peaking assets in the UK can be reduced using StartIQ™, providing greater flexibility to the UK National Grid as more and more renewables come online.

Keep an eye out for our press release with our first partner adopting StartIQ™ in the coming weeks.

Our Performance Engineering Director, Keith Douglas gives an update on the StartIQ™ fast start eCompressor validation programme, now that operational trials are underway.

We have recently been proving our newly developed fast-start electric compressor (eCompressor) technology on a natural gas peaking genset supporting the UK National Grid – we are calling this product StartIQ™.

Our StartIQ™ 2-stage eCompressor is connected to the genset internal combustion engine’s (ICE) exhaust manifold in a novel, patent-pending approach development by Bowman, injecting air during load ramps to help spin up the turbocharger faster.

When called upon by the grid, the genset immediately starts and spins up to rated speed, and as soon as it successfully synchronises with the grid, StartIQ™ kicks into action. The eCompressor accelerates from rest to more than 80,000rpm in less than 1 second, delivering ~0.4kg of air per second to the ICE’s exhaust manifold, entirely eliminating turbocharger lag all the way to 100% genset load. Once 100% genset load is achieved StartIQ™ disengages, allowing the genset to run at full load for as long as the grid requires.

The result? 0 to 100% Genset load ramp time, CO2 emissions and NOx emissions all reduced by ~90% versus the status quo.

The benefit for the customer? Reduced fuel and carbon trading costs per start, which alone give a favourable payback for StartIQ™. But on top, StartIQ™ improves the genset’s cost competitiveness for shorter duration runs, allowing the number of grid actions performed (and therefore genset revenue) to be increased on a daily basis.

The benefit for the UK National Grid and its consumers? The response times of Gigawatts of gas peaking assets in the UK can be reduced using StartIQ™, providing greater flexibility to the UK National Grid as more and more renewables come online.

Keep an eye out for our press release with our first partner adopting StartIQ™ in the coming weeks.