We have just started an exciting new project, which will integrate key manufacturing and test processes into a single centre of competence, within Bowman Power.

During the next 18 – 24 months we are planning to launch several cutting-edge new products, which will significantly increase the growth of the business. As a result, Bowman has taken a strategic decision to invest in expanding its manufacturing and test capacity and capabilities, to support the increased demands on the business and better serve our customers.

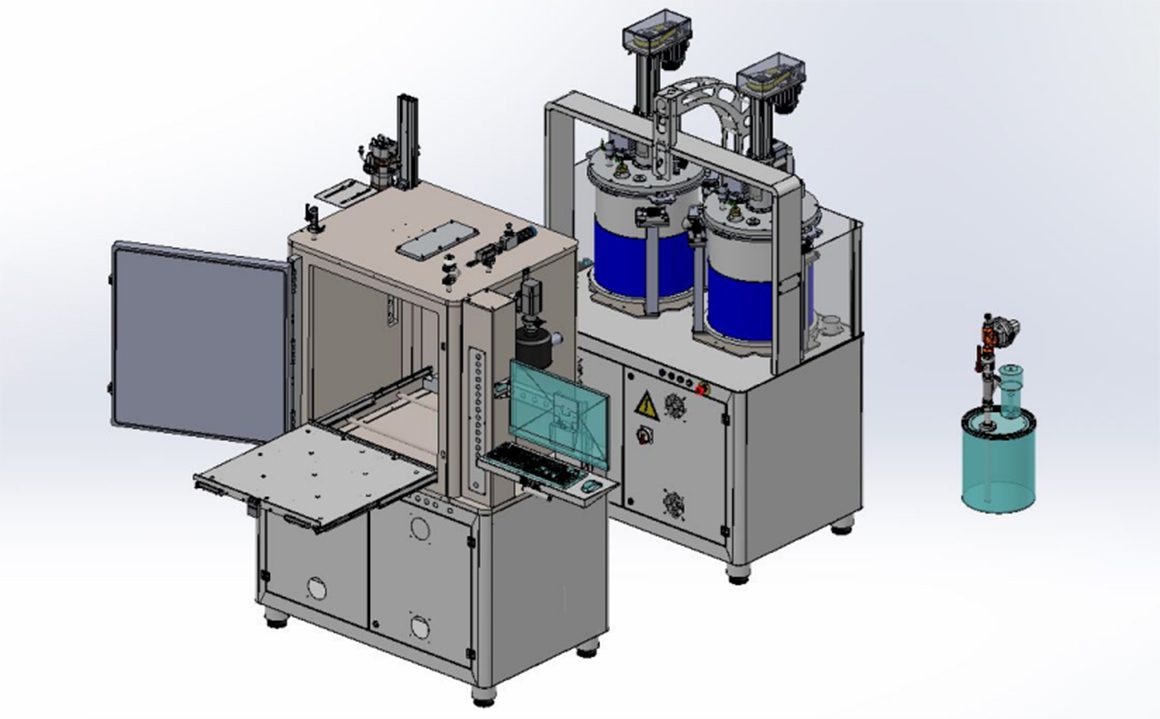

Bowman have already started the work towards setting-up a state-of-the-art new manufacturing facility, under the name Turbo Systems Electrification Centre (TSEC). This project will involve the development of a brand-new manufacturing facility, which will integrate all the existing operations together with some key processes such as shrink fitting, stator encapsulation, and automated static motor testing.

Some of the special equipment we require is already ordered. We are in discussions with multiple suppliers to firm-up detailed specifications and acceptance criteria for outstanding equipment still to be ordered. Some of this equipment will come from UK suppliers, and some will come from Northern Italy where there is a concentration of specialist electrical machine manufacturing equipment suppliers.

We have recently recruited Jordan Askiak, a highly skilled and experienced Quality Engineer who will be focused preparing and implementing Quality Assurance Strategy for the TSEC project. Further to this we are in the process of identifying and recruiting a skilled Electrical Machine Technician to support the development and implementation of new manufacturing processes and play a key role in operation of the TSEC Centre going forward.

The advanced engineering innovation and manufacturing activity required to deliver this project will drive skills development and capacity internally. It will support development of products focused on enabling a pathway to clean energy production from both combustion engines and fuel cells, making better use of fuels today, and optimising them for future fuels, such as Hydrogen, which will be essential in a Net Zero world. This is a clean and green tech manufacturing project, which will create new capability, skills and jobs.

We have just started an exciting new project, which will integrate key manufacturing and test processes into a single centre of competence, within Bowman Power.

During the next 18 – 24 months we are planning to launch several cutting-edge new products, which will significantly increase the growth of the business. As a result, Bowman has taken a strategic decision to invest in expanding its manufacturing and test capacity and capabilities, to support the increased demands on the business and better serve our customers.

Bowman have already started the work towards setting-up a state-of-the-art new manufacturing facility, under the name Turbo Systems Electrification Centre (TSEC). This project will involve the development of a brand-new manufacturing facility, which will integrate all the existing operations together with some key processes such as shrink fitting, stator encapsulation, and automated static motor testing.

Some of the special equipment we require is already ordered. We are in discussions with multiple suppliers to firm-up detailed specifications and acceptance criteria for outstanding equipment still to be ordered. Some of this equipment will come from UK suppliers, and some will come from Northern Italy where there is a concentration of specialist electrical machine manufacturing equipment suppliers.

We have recently recruited Jordan Askiak, a highly skilled and experienced Quality Engineer who will be focused preparing and implementing Quality Assurance Strategy for the TSEC project. Further to this we are in the process of identifying and recruiting a skilled Electrical Machine Technician to support the development and implementation of new manufacturing processes and play a key role in operation of the TSEC Centre going forward.

The advanced engineering innovation and manufacturing activity required to deliver this project will drive skills development and capacity internally. It will support development of products focused on enabling a pathway to clean energy production from both combustion engines and fuel cells, making better use of fuels today, and optimising them for future fuels, such as Hydrogen, which will be essential in a Net Zero world. This is a clean and green tech manufacturing project, which will create new capability, skills and jobs.

We have just started an exciting new project, which will integrate key manufacturing and test processes into a single centre of competence, within Bowman Power.

During the next 18 – 24 months we are planning to launch several cutting-edge new products, which will significantly increase the growth of the business. As a result, Bowman has taken a strategic decision to invest in expanding its manufacturing and test capacity and capabilities, to support the increased demands on the business and better serve our customers.

Bowman have already started the work towards setting-up a state-of-the-art new manufacturing facility, under the name Turbo Systems Electrification Centre (TSEC). This project will involve the development of a brand-new manufacturing facility, which will integrate all the existing operations together with some key processes such as shrink fitting, stator encapsulation, and automated static motor testing.

Some of the special equipment we require is already ordered. We are in discussions with multiple suppliers to firm-up detailed specifications and acceptance criteria for outstanding equipment still to be ordered. Some of this equipment will come from UK suppliers, and some will come from Northern Italy where there is a concentration of specialist electrical machine manufacturing equipment suppliers.

We have recently recruited Jordan Askiak, a highly skilled and experienced Quality Engineer who will be focused preparing and implementing Quality Assurance Strategy for the TSEC project. Further to this we are in the process of identifying and recruiting a skilled Electrical Machine Technician to support the development and implementation of new manufacturing processes and play a key role in operation of the TSEC Centre going forward.

The advanced engineering innovation and manufacturing activity required to deliver this project will drive skills development and capacity internally. It will support development of products focused on enabling a pathway to clean energy production from both combustion engines and fuel cells, making better use of fuels today, and optimising them for future fuels, such as Hydrogen, which will be essential in a Net Zero world. This is a clean and green tech manufacturing project, which will create new capability, skills and jobs.