A Bowman ETC1000 eTurbine has hit the landmark figure of generating 1.5 million kWh of additional free energy. Read on to find out how...

Location: UK

Customer: Viridor

Engine: Jenbacher J320

Product: eTurbine (ETC 1000)

Fuel type: Landfill gas

Sector: Recycling and waste

The customer

Viridor is a UK business that supports the growth of a circular economy. They do this by seeking to keep resources in use for as long as possible and recovering energy from materials at the end of their service life. Whether those resources are collected by their vehicles from local businesses or delivered into one of their Energy Recovery Facilities, they transform ‘waste’ into materials and energy that society can use.

Across 18 active landfill sites, Viridor recovers energy from non-recyclable waste using anaerobic digestion, gas extraction and thermal technologies. Energy is recovered by burning the biogas in an advanced lean-burn gas generator to generate electricity for export to the National Grid. This provides a greener source of energy and reduces the level of methane emissions released into the atmosphere from waste disposal.

Results:

- Over 25,000 hours uninterrupted running

- 5% additional free power generated for the same fuel input

- 6.6% increase in overall power density

- 32% reduction in unburnt hydrocarbon emissions (UHC)

- 15% reduction in greenhouse gas (CO2 equivalent) emissions

- 1.5 million kWh additional energy generated to date (since initial trials started)

- Thousands of tonnes (CO2 equivalent) of CH4 prevented from entering the atmosphere

The challenge

Viridor has a waste disposal site in Calne, UK, that includes a closed landfill site. As part of their commitment to the circular economy the site was capped and landfill gas is being extracted. This captured gas is then used to power generator sets (gensets) in order to create renewable power, which is sold back to the UK grid.

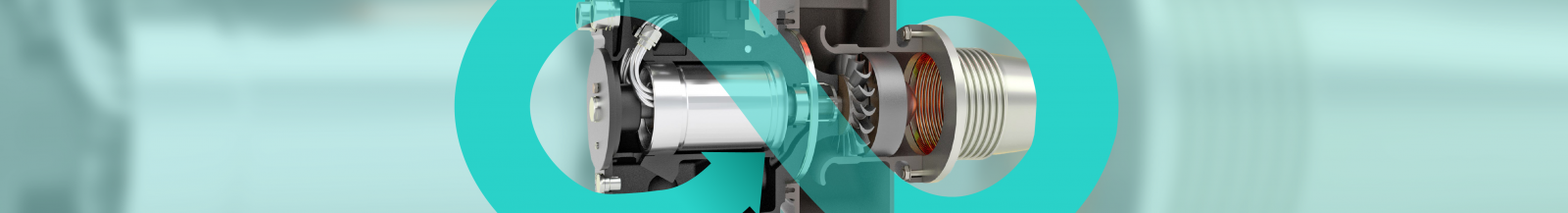

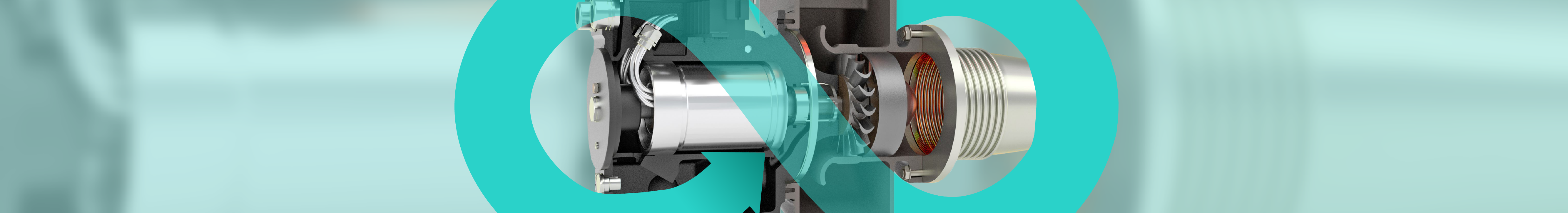

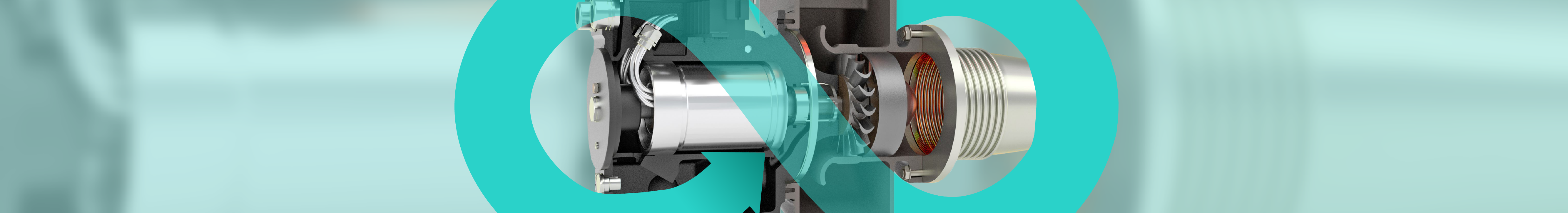

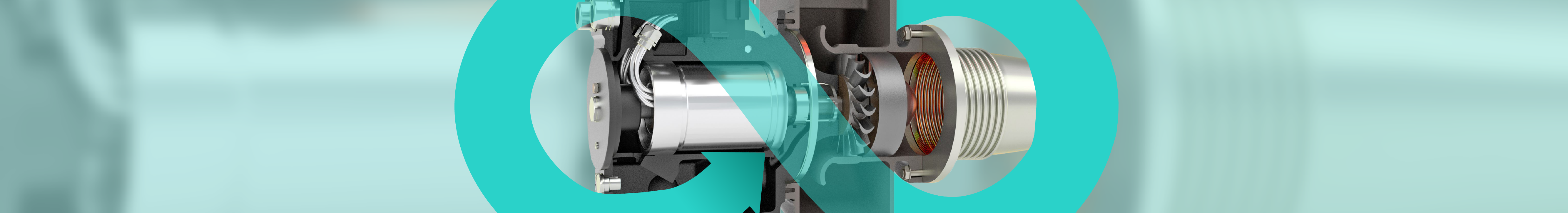

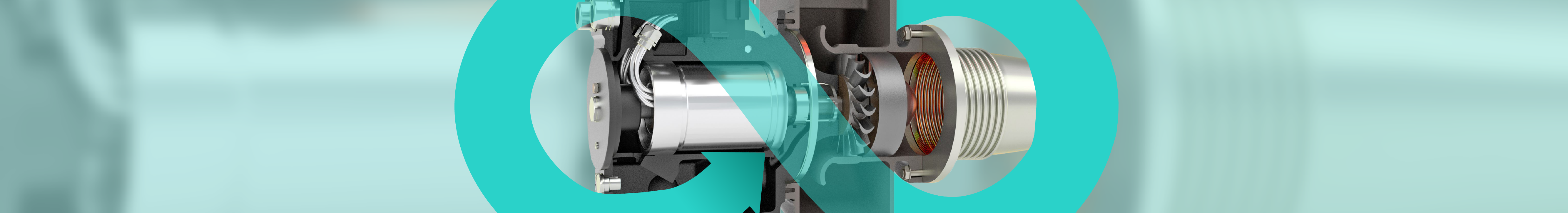

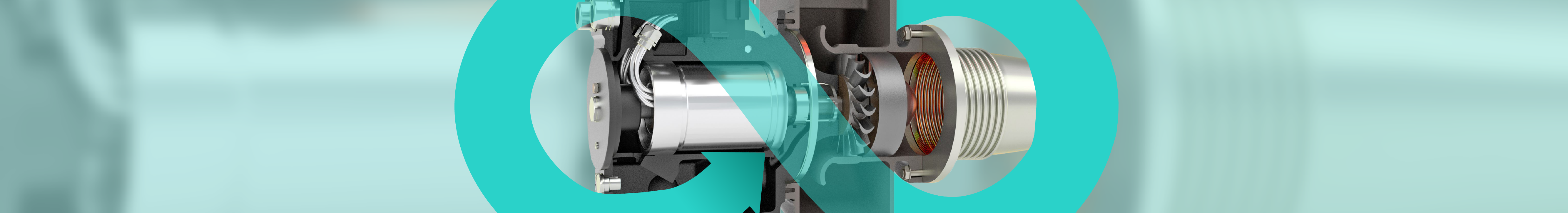

Across the site, Viridor has 3 containerised INNIO Jenbacher J320 gensets, all running on landfill gas. To maximise the use of these engines and improve efficiency, Viridor sought out Bowman’s eTurbine system. The eTurbine system recovers otherwise wasted heat energy from the engine’s exhaust and converts it into free, additional and useful electrical power.

The solution

Bowman recommended the ETC 1000 eTurbine, their most cost effective, reliable and efficient eTurbine. The eTurbine system represented an opportunity for the customer to increase the efficiency of the engine and power output, whilst also reducing their emissions from power generation.

Bowman conducted the installation with support from CooperÖstlund, a well-known UK provider of installation and maintenance services to the power industry. Although the genset was contained in a small space, there were no significant challenges and no major modifications were made to the host container. The installation was completed on time and on budget thanks to cooperation from all three parties.

The results

Within just a few weeks of operation, Bowman had successfully boosted the engine efficiency and power output of Viridor’s gensets. They also demonstrated a 15% reduction in CO2 equivalent emissions and a 32% reduction in UHC emissions. This proved to be a significant decrease, given the very high methane content of landfill gas.

Through using Bowman’s eTurbine system, Viridor were able to reduce energy lost to the engine exhaust and maintain a consistent supply of power to the National Grid. As of April 2022, the eTurbine system has been running for nearly two years and has generated over 1,500,000 kWh of additional energy.

Bowman also supported Viridor in seeking approval from OFGEM, the government regulator for gas and electricity markets in Great Britain, for operation of the eTurbine on an accredited site. This ensured that the eTurbine system could be used without affecting their ability to claim Renewable Obligation Certificates (ROCs) on the host genset’s output.

Paul Dowman-Tucker, CEO of Bowman Power said “The Bowman team is proud to have delivered such fantastic performance results for Viridor, on what we hope will be the first of many projects in the UK landfill gas sector. We are particularly thrilled to have demonstrated on an operational site the substantial reductions in greenhouse gas emissions that can be achieved using our technology, particularly the avoidance of the emission of thousands of tonnes of methane. We look forward to further working with Viridor.”

A Bowman ETC1000 eTurbine has hit the landmark figure of generating 1.5 million kWh of additional free energy. Read on to find out how...

Location: UK

Customer: Viridor

Engine: Jenbacher J320

Product: eTurbine (ETC 1000)

Fuel type: Landfill gas

Sector: Recycling and waste

The customer

Viridor is a UK business that supports the growth of a circular economy. They do this by seeking to keep resources in use for as long as possible and recovering energy from materials at the end of their service life. Whether those resources are collected by their vehicles from local businesses or delivered into one of their Energy Recovery Facilities, they transform ‘waste’ into materials and energy that society can use.

Across 18 active landfill sites, Viridor recovers energy from non-recyclable waste using anaerobic digestion, gas extraction and thermal technologies. Energy is recovered by burning the biogas in an advanced lean-burn gas generator to generate electricity for export to the National Grid. This provides a greener source of energy and reduces the level of methane emissions released into the atmosphere from waste disposal.

Results:

- Over 25,000 hours uninterrupted running

- 5% additional free power generated for the same fuel input

- 6.6% increase in overall power density

- 32% reduction in unburnt hydrocarbon emissions (UHC)

- 15% reduction in greenhouse gas (CO2 equivalent) emissions

- 1.5 million kWh additional energy generated to date (since initial trials started)

- Thousands of tonnes (CO2 equivalent) of CH4 prevented from entering the atmosphere

The challenge

Viridor has a waste disposal site in Calne, UK, that includes a closed landfill site. As part of their commitment to the circular economy the site was capped and landfill gas is being extracted. This captured gas is then used to power generator sets (gensets) in order to create renewable power, which is sold back to the UK grid.

Across the site, Viridor has 3 containerised INNIO Jenbacher J320 gensets, all running on landfill gas. To maximise the use of these engines and improve efficiency, Viridor sought out Bowman’s eTurbine system. The eTurbine system recovers otherwise wasted heat energy from the engine’s exhaust and converts it into free, additional and useful electrical power.

The solution

Bowman recommended the ETC 1000 eTurbine, their most cost effective, reliable and efficient eTurbine. The eTurbine system represented an opportunity for the customer to increase the efficiency of the engine and power output, whilst also reducing their emissions from power generation.

Bowman conducted the installation with support from CooperÖstlund, a well-known UK provider of installation and maintenance services to the power industry. Although the genset was contained in a small space, there were no significant challenges and no major modifications were made to the host container. The installation was completed on time and on budget thanks to cooperation from all three parties.

The results

Within just a few weeks of operation, Bowman had successfully boosted the engine efficiency and power output of Viridor’s gensets. They also demonstrated a 15% reduction in CO2 equivalent emissions and a 32% reduction in UHC emissions. This proved to be a significant decrease, given the very high methane content of landfill gas.

Through using Bowman’s eTurbine system, Viridor were able to reduce energy lost to the engine exhaust and maintain a consistent supply of power to the National Grid. As of April 2022, the eTurbine system has been running for nearly two years and has generated over 1,500,000 kWh of additional energy.

Bowman also supported Viridor in seeking approval from OFGEM, the government regulator for gas and electricity markets in Great Britain, for operation of the eTurbine on an accredited site. This ensured that the eTurbine system could be used without affecting their ability to claim Renewable Obligation Certificates (ROCs) on the host genset’s output.

Paul Dowman-Tucker, CEO of Bowman Power said “The Bowman team is proud to have delivered such fantastic performance results for Viridor, on what we hope will be the first of many projects in the UK landfill gas sector. We are particularly thrilled to have demonstrated on an operational site the substantial reductions in greenhouse gas emissions that can be achieved using our technology, particularly the avoidance of the emission of thousands of tonnes of methane. We look forward to further working with Viridor.”

A Bowman ETC1000 eTurbine has hit the landmark figure of generating 1.5 million kWh of additional free energy. Read on to find out how...

Location: UK

Customer: Viridor

Engine: Jenbacher J320

Product: eTurbine (ETC 1000)

Fuel type: Landfill gas

Sector: Recycling and waste

The customer

Viridor is a UK business that supports the growth of a circular economy. They do this by seeking to keep resources in use for as long as possible and recovering energy from materials at the end of their service life. Whether those resources are collected by their vehicles from local businesses or delivered into one of their Energy Recovery Facilities, they transform ‘waste’ into materials and energy that society can use.

Across 18 active landfill sites, Viridor recovers energy from non-recyclable waste using anaerobic digestion, gas extraction and thermal technologies. Energy is recovered by burning the biogas in an advanced lean-burn gas generator to generate electricity for export to the National Grid. This provides a greener source of energy and reduces the level of methane emissions released into the atmosphere from waste disposal.

Results:

- Over 25,000 hours uninterrupted running

- 5% additional free power generated for the same fuel input

- 6.6% increase in overall power density

- 32% reduction in unburnt hydrocarbon emissions (UHC)

- 15% reduction in greenhouse gas (CO2 equivalent) emissions

- 1.5 million kWh additional energy generated to date (since initial trials started)

- Thousands of tonnes (CO2 equivalent) of CH4 prevented from entering the atmosphere

The challenge

Viridor has a waste disposal site in Calne, UK, that includes a closed landfill site. As part of their commitment to the circular economy the site was capped and landfill gas is being extracted. This captured gas is then used to power generator sets (gensets) in order to create renewable power, which is sold back to the UK grid.

Across the site, Viridor has 3 containerised INNIO Jenbacher J320 gensets, all running on landfill gas. To maximise the use of these engines and improve efficiency, Viridor sought out Bowman’s eTurbine system. The eTurbine system recovers otherwise wasted heat energy from the engine’s exhaust and converts it into free, additional and useful electrical power.

The solution

Bowman recommended the ETC 1000 eTurbine, their most cost effective, reliable and efficient eTurbine. The eTurbine system represented an opportunity for the customer to increase the efficiency of the engine and power output, whilst also reducing their emissions from power generation.

Bowman conducted the installation with support from CooperÖstlund, a well-known UK provider of installation and maintenance services to the power industry. Although the genset was contained in a small space, there were no significant challenges and no major modifications were made to the host container. The installation was completed on time and on budget thanks to cooperation from all three parties.

The results

Within just a few weeks of operation, Bowman had successfully boosted the engine efficiency and power output of Viridor’s gensets. They also demonstrated a 15% reduction in CO2 equivalent emissions and a 32% reduction in UHC emissions. This proved to be a significant decrease, given the very high methane content of landfill gas.

Through using Bowman’s eTurbine system, Viridor were able to reduce energy lost to the engine exhaust and maintain a consistent supply of power to the National Grid. As of April 2022, the eTurbine system has been running for nearly two years and has generated over 1,500,000 kWh of additional energy.

Bowman also supported Viridor in seeking approval from OFGEM, the government regulator for gas and electricity markets in Great Britain, for operation of the eTurbine on an accredited site. This ensured that the eTurbine system could be used without affecting their ability to claim Renewable Obligation Certificates (ROCs) on the host genset’s output.

Paul Dowman-Tucker, CEO of Bowman Power said “The Bowman team is proud to have delivered such fantastic performance results for Viridor, on what we hope will be the first of many projects in the UK landfill gas sector. We are particularly thrilled to have demonstrated on an operational site the substantial reductions in greenhouse gas emissions that can be achieved using our technology, particularly the avoidance of the emission of thousands of tonnes of methane. We look forward to further working with Viridor.”